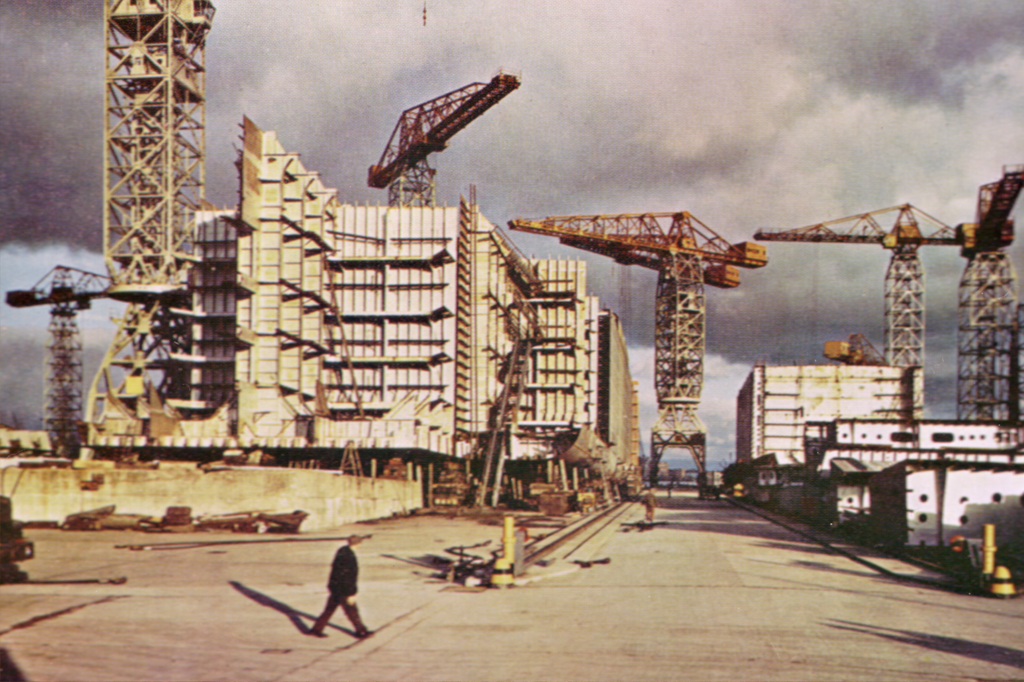

Samson and GoliathThe cranes, are of Krupp Ardelt design, modified to meet Harland and Wolff's special requirements. The first, Goliath, completed in July 1969, was largely constructed by Harland and Wolff in the Belfast shipyard, the second, Samson, was provided in its entirety by Krupps and was completed in May 1974.

In most respects the cranes are identical but Samson is some 10m higher than the Goliath. Each has a span of 140m (460 feet) and a safe working load of 840 tonnes. Goliath has a height from rail tracks to the underside of the bridge girders of 70m (230 feet) and an overall height of 96m (316 feet). Samson has an overall height of 106m (348 feet) with a height of 80m (263 feet) from tracks to the underside of bridge girders.

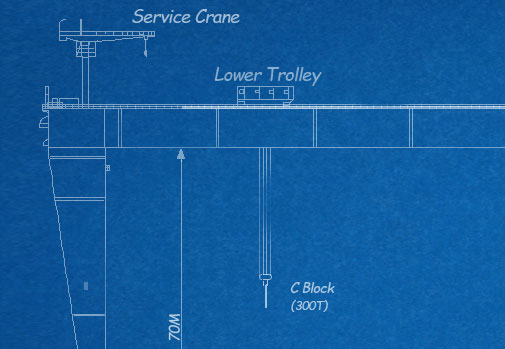

Each crane consists basically of the pier (Box) leg, the sheer (Tube) legs, the bridge girders, and two lifting trolleys. The pier leg is of box construction and contains a stairway to the bridge girders and a four-man lift which operates at a speed of 0.5 m/sec. for a height of about 54.4m (180 feet); in the case of Samson the height is 70.4m (232 feet).

The crane bridge is of twin box girder design and on one side is rigidly connected to the pier leg. On the other side it bears against the sheer leg through an end sill. The trolleys can traverse the whole length of the bridge girder, the lower trolley passing beneath the upper trolley. The overall heights of the two trolleys are upper 9.5m (31ft. 1½ins.) and lower 4.32m (14ft. 1in.).

The upper trolley has two hoists, each of 300 tonnes capacity which are arranged symmetrically outside the bridge girders, and an auxiliary hoist of 15 tonnes capacity. The lower trolley has a hoist of 300 tonnes' capacity operating between the bridge girders.

In addition to lifting gear the upper trolley also carries the driver's cab which is attached to an outrigger. The cab affords all-round vision for the driver who is in telephonic communication with a number of points on the crane itself, and in U.H.F. radio communication with the ground. The Goliath cab is fixed while the Samson cab can be slewed.

A suitable safety device is available to the driver for emergency use.

Upper and lower trolleys are driven by trolley travel gears and all trackwheels can be driven or braked.

A maintenance slewing crane of 13 tonnes capacity is arranged on top of the pier leg, and can directly pick up components out of the trolleys and the machinery room and lower these to the ground. The radius and lifting capacity of this crane is suitable for the heaviest machinery components.

The cranes run on an 800m track which spans the dock and the block assembly area where large weldments are made up. The loaded weight of each crane - approximately 4000 tonnes - is taken on 64 special anti-friction bearing mounted wheels, each of 90.2cm (35½ins.) diameter. Twelve identical driving motors are fitted - six to each leg - so arranged to provide direct drive to 36 of the wheels. Hydraulically-operated rail clamps are fitted to prevent the crane from being blown along the track in high winds.

In operation each crane moves along the track at a speed of about 30 metres (98 feet) per minute, although this can be increased to 45 metres (147 feet) per minute for loads of 100 tonnes or less.

Special devices ensure that the legs move at identical speeds, thus preventing skewing.

If, however, the legs should become more than 250 mm out of step the drive to all wheels is automatically cut off.

In the skewed position only the sheer leg can be moved until correct alignment is regained with the pier leg.

Extensive safety devices and electrical interlocks are provided for all movements and operating conditions.

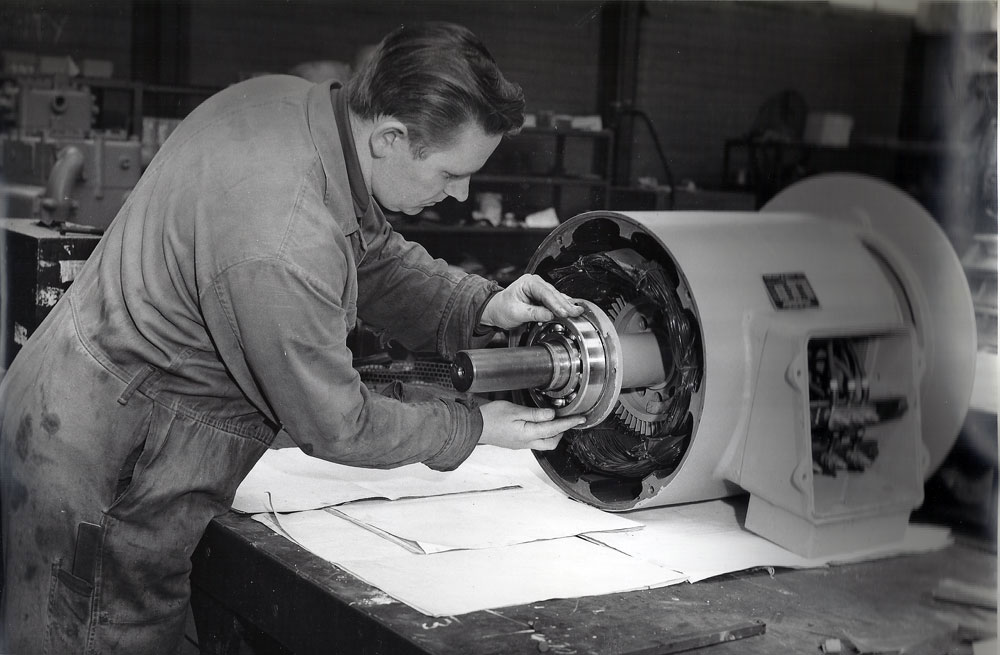

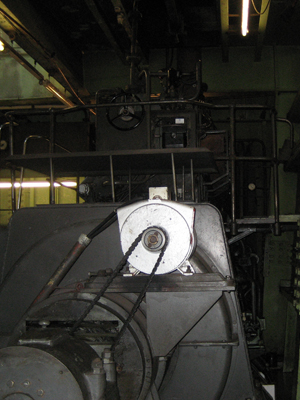

An interesting and unique feature of the cranes is that they are powered by electricity generated on board.

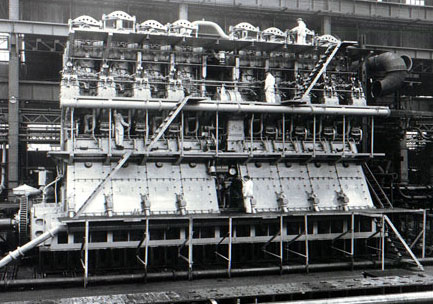

The generating plant is installed in the top section of the pier leg and consists of the following: - Two Ruston AR2 1350 b.h.p. 750 r.p.m. main diesel engines, each driving two x 365 KW. 600V D.C. generators directly coupled, and one 90 KW 600V D.C. and one 45 KW 300V. D.C. generators belt-driven at twice engine speed. The two 365 Kw. generators supply power for the main hoisting movements, while the smaller generators supply power for the Upper Trolley and Lower Trolley cross-travel motors respectively. A braking alternator is also directly attached to each main diesel engine shaft to provide regenerative braking when necessary.

In addition to the two main diesel-generating installations each crane is also equipped with two 170 h.p. Ruston diesels which each drive a 120 KW 440V three-phase alternator to give supplies to pumps, lighting, lift, and maintenance crane and also control voltages through transformers.

Speciffically, only one of these diesel alternators is needed for the operation of the Samson crane, the second merely acting as standby. For full operation Goliath requires both engines running.

Now much beloved Belfast landmarks, their future was assured in 2003 when they were scheduled for preservation.

|

|

The PartnersHarland, Wolff, Pirrie and Wilson

The PartnersHarland, Wolff, Pirrie and Wilson

The HatsChairmen, MD's, CEO's

The HatsChairmen, MD's, CEO's

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Charles PalmourChairman 1941-1944

Sir Charles PalmourChairman 1941-1944

John S BallieChairman 1962-1965

John S BallieChairman 1962-1965

Dr Dennis RebbeckChairman 1965-1966

Dr Dennis RebbeckChairman 1965-1966

Sir John MallabarChairman 1966-1970

Sir John MallabarChairman 1966-1970

Joe R EdwardsChairman 1970

Joe R EdwardsChairman 1970

Alan WattActing Chairman 1970-1971

Alan WattActing Chairman 1970-1971

Lord RochdaleChairman 1971- 1975

Lord RochdaleChairman 1971- 1975

Sir Brian MortonChairman 1975-1980

Sir Brian MortonChairman 1975-1980

Victor Alexander CookeChairman 1980-1981)

Victor Alexander CookeChairman 1980-1981)

Vivian WadsworthChairman 1981-1982

Vivian WadsworthChairman 1981-1982

Sir John ParkerChairman 1982-1992

Sir John ParkerChairman 1982-1992

Islandmen(and Women)

Islandmen(and Women)

Save our ShipyardSupport and solidarity

Save our ShipyardSupport and solidarity

The War MemorialsWe Will Remember Them

The War MemorialsWe Will Remember Them

The Bible Class

The Bible Class

Nicknames

Nicknames

The Yarns(and Tall Tales)

The Yarns(and Tall Tales)

The Shipyard IndentureJW Mullholland

The Shipyard IndentureJW Mullholland