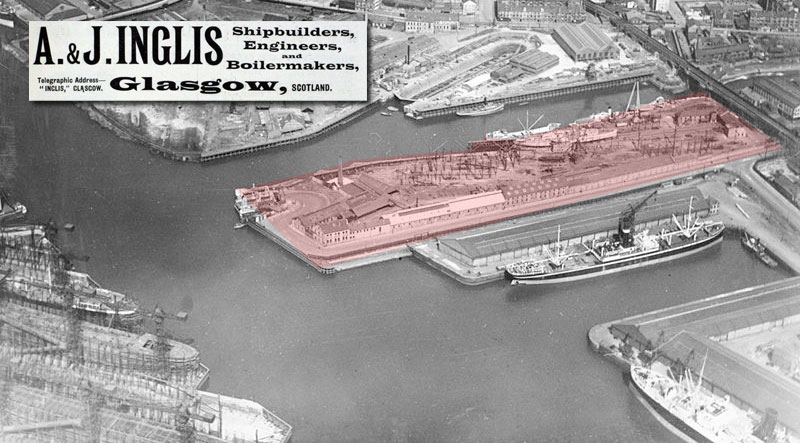

Located on the east side of the River Kelvin at its confluence with the River Clyde, the Pointhouse shipbuilding yard of A&J Inglis Ltd occupied a narrow strip of land that limited the size of vessels which could be built there. It was hemmed in between the 'Iron Bridge', a former footbridge that was appended to the structure carrying the Glasgow north bank suburban railway line over the River Kelvin, and Ferry Road which used to be the north embarkation point for the long abandoned Govan vehicular and passenger ferries. The yard was sold by its founder Dr John Inglis to Harland & Wolff Ltd of Belfast in 1919 with a pre-condition that both of his sons were employed as directors for as long as they wished to do so.

The minuscule Partick shipyard regularly turned out a mixed bag of barges, coasters, dredgers, tenders and tugs frequently interspersed with the occasional small specialised passenger ferry or small cargo liner.

A successful product from the small shipyard, which would be reprehensibly abhorred today, was a series of 17 whale catcher ships built for British and Norwegian owners between 1948 and 1953. Some of these vessels were fitted with steam reciprocating engines, steering gear, stern-frame, shafting and propellers purloined from redundant former Royal Navy Flower class corvettes, which were winched up the 'Pointhouse Slip', and broken up in situ by the shipyard employees. Thirteen of these vessels were for: United Whalers (UK) Ltd, who had ordered the whale factory ship Balena from the parent company's Belfast shipyard and needed a complement of catchers.

Probably the most famous vessels built by A&J Inglis Ltd were the paddle steamers Waverley 632 g.r.t. and Maid of the Loch 555 g.r.t. |

The latter vessel was bolt assembled in kit form on one of the Pointhouse slipways, marked and colour coded (red for port, green for starboard), dismantled, then transported in small sections by road or rail to Balloch where the units were re-erected on British Railways repair slipway.

............Maid of the Loch

This adaptable manufacturing technique was then possible due to the combination of riveting and bolting construction methods which were still very much in use in 1953. The completed ship was launched into Loch Lomond where she plied for many years before dwindling patronage led to her being mothballed in 1981. After many years of neglect during which she became a vandal prone hulk and nearly sank, she was bought by the former Dumbarton District Council in 1992. She is now under protracted restoration under the aegis of the Loch Lomond Steamship Company, supported by some enthusiastic volunteers and a few like-minded Scottish companies. Prior to the completion of the Maid of the Loch, the paddle steamer Waverley had been launched by the yard in 1946, although her fame was not to come to hand until the late 1970s when she became the world's last ocean going paddle steamer. She has since seen many voyages from various ports and seaside resorts throughout the UK, latterly being berthed in the City of Glasgow, where she still performs 'trips doon the watter'.

The small shipyard, whilst visibly in possession of antiquated shipbuilding hardware, regularly produced fine looking vessels that saw reliable service for their owners throughout the world. In addition to shipbuilding, the company undertook ongoing repair work on coasters and pleasure steamers that regularly plied the Firth of Clyde and UK inshore waters. |

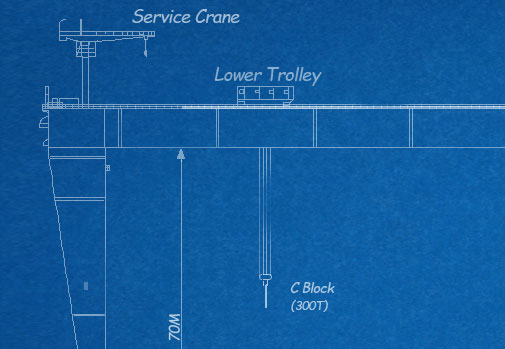

These tasks were usually carried out on the patented winch operated slipway, which was a large carriage running on four rails set into a declivity berth with keel and bilge blocks mounted on its top. This system slowly enabled ships to be pulled out of the water for extensive hull examination and subsequent renovation. It was extensively upgraded in 1952 and remained in use for the next decade. Hoisting of material was performed by a few fixed Scotch derricks, with limited lifting capacity that were located alongside the berths. Their restricted ability created only minor encumbrances, as the small types of ship constructed at Pointhouse did not generate the raising of heavy constituent components. The yard retained a set of 80 ton 'shear legs' similar to those in existence at a handful of other West of Scotland shipyards. This robust tripod-like machine helped to create a site of industrial antiquity that belied the modernity of the ships built at Pointhouse in the post-war era.

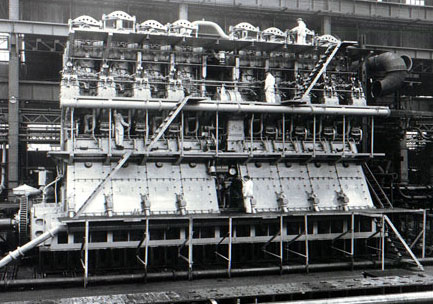

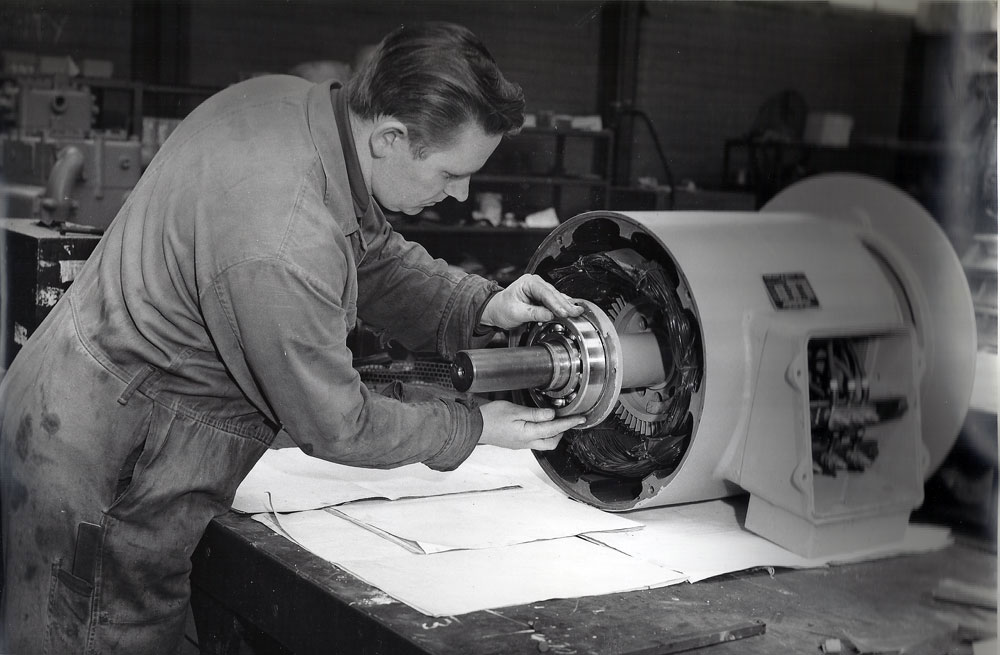

This dated Edwardian lifting equipment was regularly used to assist the installation of boilers and machinery into the craft that Inglis built. Most of these engines of the steam reciprocating type were built in the yard's engine works located two miles east of the Pointhouse site at Anderston. The company also had a small boiler works which was situated north of the Iron Bridge and was latterly used as a fabrication shop. The more modern craft built by the yard tended to use diesels that were built by other UK specialist engine builders. |

The shipyard fell foul of the non-Irish policy of retrenchment conjured by its parent company at the same time as its sister group repair yard of D&W Henderson Ltd, on the opposite bank of the River Kelvin, was also being abandoned. Both facilities stopped shipbuilding and ship repair work in l961 respectively. The last ship built at Pointhouse was the self-propelled motor hopper barge Aigburth 1037 g.r.t. (yard no.1645P) built for British Transport Docks Liverpool. Despite her mundane role she was graced with a handsome futuristic profile of integrated superstructure, funnel and mast, and viewed from the waterline looked more like a coaster than a spoil vessel.

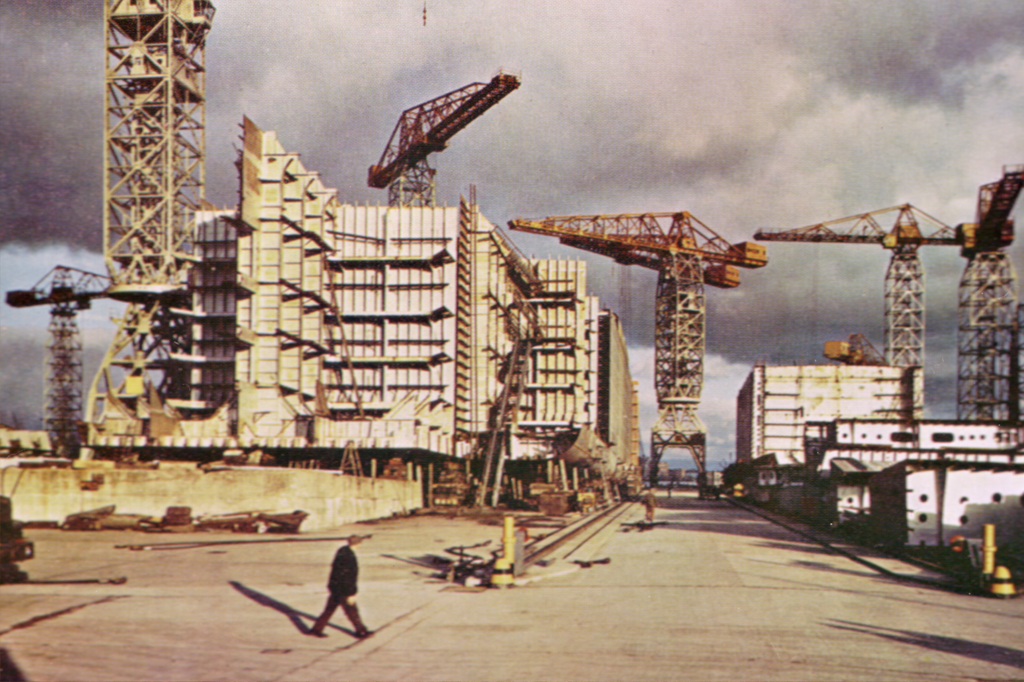

In the period from 1946 until 1962, the shipyard built 60 vessels of 33,897 g.r.t. comprising 26% for export. It employed at its peak over 600 workers during the zenith of concurrent shipbuilding and ship repairing activities of the early '50s. The largest vessel built at the yard during this period was the m. v. Soochow 3154 g.r.t., a refrigerated cargo passenger vessel built under subcontract from Scotts of Greenock and launched on 23 April 1947 for the China Navigation Co Ltd of London. After closure the site lay abandoned and derelict for a number of years until the buildings, cranes and shear legs were demolished.

Opened in 2011 Glasgows' new £80m Riverside Museum (of Transport and maritime heritage) on Pointhouse Quay at the confluence of the Rivers Clyde and Kelvin. The titanium and glass clad museum building occupies the site of the famous Glasgow shipyard, the Pointhouse yard, opened in 1863 by the brothers Anthony and John Inglis.

|

The picture above depicts Inglis' shipyard from the bridge over the River Kelvin in 1946. Nearest the camera is the Clyde paddle steamer Jeanie Deans (originally built at Fairfields on the opposite bank of the Clyde in Govan in 1931) undergoing a significant rebuild after over six years service in the Royal Navy as HMS Jeanie Deans during WW2. The vessel immediately astern of her and the vessel under construction in the yard are two of the four tankers, Empire Tedport, Empire Tedship, Empire Tedmuir and Empire Tedrita, built by Inglis in 1946-47. Finally, still in her austere wartime livery is the paddler HMS Aristocrat, then recently arrived after demob from the Royal Navy and ready to be converted back into her civilian role as the Clyde-based paddler Talisman. She was an Inglis product in 1935 when she broke new ground as the Clyde's first and, as it turned out, only diesel electric paddle vessel.

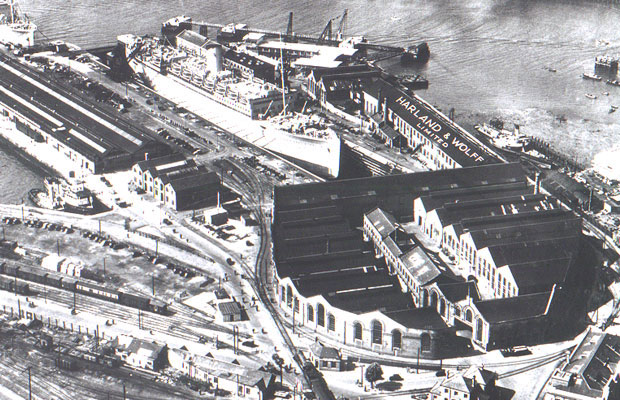

The high cranes in the background are those at the Govan shipyard of the huge Harland & Wolff shipbuilding group, of which the Inglis company had been a subsidiary since 1919. It Included 6 shipyards, the Finnieston (Steam) Engine Works at Anderston Quay, the Scotstoun (Diesel) Engine Works and the huge Clyde Foundry, one of the largest in Europe, in Helen Street Govan, which produced massive castings such as engine cylinder blocks, stern posts and rudder horns, etc. |

The PartnersHarland, Wolff, Pirrie and Wilson

The PartnersHarland, Wolff, Pirrie and Wilson

The HatsChairmen, MD's, CEO's

The HatsChairmen, MD's, CEO's

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Charles PalmourChairman 1941-1944

Sir Charles PalmourChairman 1941-1944

John S BallieChairman 1962-1965

John S BallieChairman 1962-1965

Dr Dennis RebbeckChairman 1965-1966

Dr Dennis RebbeckChairman 1965-1966

Sir John MallabarChairman 1966-1970

Sir John MallabarChairman 1966-1970

Joe R EdwardsChairman 1970

Joe R EdwardsChairman 1970

Alan WattActing Chairman 1970-1971

Alan WattActing Chairman 1970-1971

Lord RochdaleChairman 1971- 1975

Lord RochdaleChairman 1971- 1975

Sir Brian MortonChairman 1975-1980

Sir Brian MortonChairman 1975-1980

Victor Alexander CookeChairman 1980-1981)

Victor Alexander CookeChairman 1980-1981)

Vivian WadsworthChairman 1981-1982

Vivian WadsworthChairman 1981-1982

Sir John ParkerChairman 1982-1992

Sir John ParkerChairman 1982-1992

Islandmen(and Women)

Islandmen(and Women)

Save our ShipyardSupport and solidarity

Save our ShipyardSupport and solidarity

The War MemorialsWe Will Remember Them

The War MemorialsWe Will Remember Them

The Bible Class

The Bible Class

Nicknames

Nicknames

The Yarns(and Tall Tales)

The Yarns(and Tall Tales)

The Shipyard IndentureJW Mullholland

The Shipyard IndentureJW Mullholland