A section of the Foyle Bridge loaded onto a barge for transportation to site.

Bridge Construction

A number of bridge fabrication projects have now

been carried out by the yard across the UK and

Ireland. Harland and Wolff declined to develop

bridge initial design capability, in favour of

working with experienced partners. Harland and

Wolff’s strengths in this area are shop drawings,

procurement, sub-assembly, final assembly,

blasting, painting. delivery, and installation of

bridges.

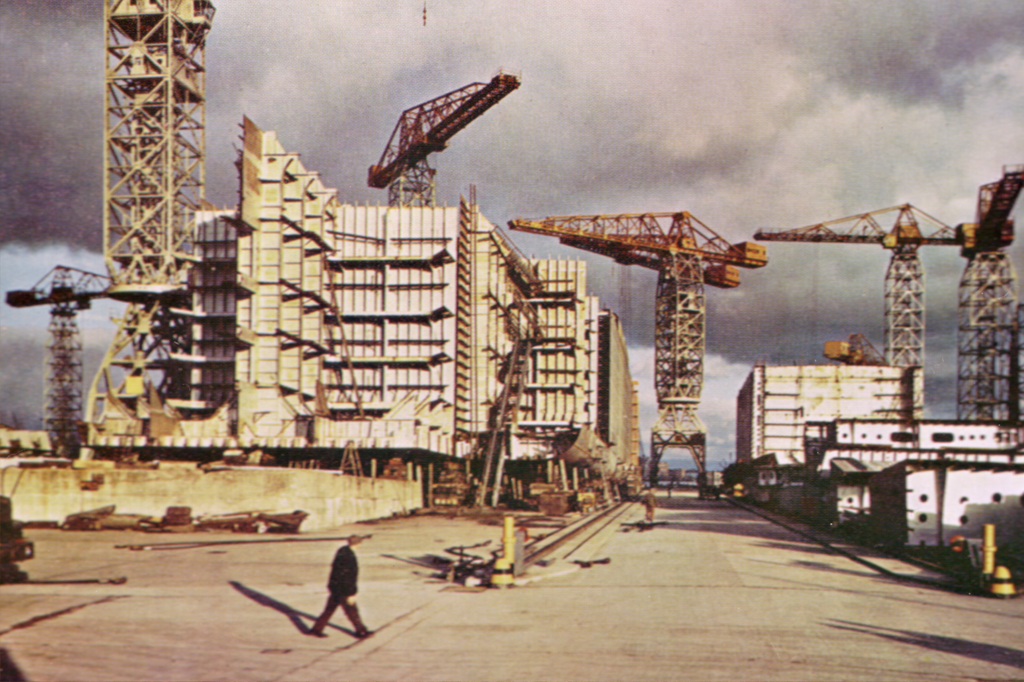

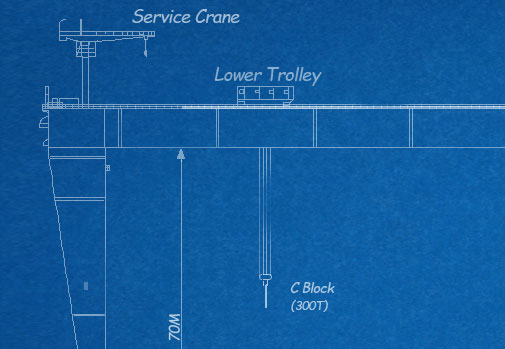

(left) The three main river spans of the Foyle Bridge are of steel box construction and were built in 6 segments, they weighed up to 900 tonnes each. They where transported by barge and ocean-going tug to site where they were lifted into position.

(left) In 2005 the yard was contracted by Balfour

Beatty (Aberdeen) to supply. fabricate, paint.

and install the Montrose Bridge, in sections.

This

structure had a weight of 700tonnes and took

two months to build and one month to install.

Harland and Wolff utilised the crane barge

Mersey Mammoth to deliver and install the

bridge sections to their final destination.

This allowed reduced on-site (and overall) costs by installing larger bridge elements.

The Twelve Quays linkspan being loaded onto a pontoon for transportation to site

The Mardyke foot bridge is a glistening white steel tubular structure weighing 65 tonnes.

(above) The 500 tonnes Holyhead Linkspan during tow-away.

(left)Completed in 2005 the Mardyke bridge, commissioned by Cork County Council was designed by Fehily Timoney Gifford, built in the Harland & Wolff yard and transported to Cork in sections.

Opened on the 16th June 2003 the James Joyce Bridge was built by Irishenco Construction, using pre-fabricated steel sections manufactured by Harland and Wolff.

|

|

The PartnersHarland, Wolff, Pirrie and Wilson

The PartnersHarland, Wolff, Pirrie and Wilson

The HatsChairmen, MD's, CEO's

The HatsChairmen, MD's, CEO's

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Charles PalmourChairman 1941-1944

Sir Charles PalmourChairman 1941-1944

John S BallieChairman 1962-1965

John S BallieChairman 1962-1965

Dr Dennis RebbeckChairman 1965-1966

Dr Dennis RebbeckChairman 1965-1966

Sir John MallabarChairman 1966-1970

Sir John MallabarChairman 1966-1970

Joe R EdwardsChairman 1970

Joe R EdwardsChairman 1970

Alan WattActing Chairman 1970-1971

Alan WattActing Chairman 1970-1971

Lord RochdaleChairman 1971- 1975

Lord RochdaleChairman 1971- 1975

Sir Brian MortonChairman 1975-1980

Sir Brian MortonChairman 1975-1980

Victor Alexander CookeChairman 1980-1981)

Victor Alexander CookeChairman 1980-1981)

Vivian WadsworthChairman 1981-1982

Vivian WadsworthChairman 1981-1982

Sir John ParkerChairman 1982-1992

Sir John ParkerChairman 1982-1992

Islandmen(and Women)

Islandmen(and Women)

Save our ShipyardSupport and solidarity

Save our ShipyardSupport and solidarity

The War MemorialsWe Will Remember Them

The War MemorialsWe Will Remember Them

The Bible Class

The Bible Class

Nicknames

Nicknames

The Yarns(and Tall Tales)

The Yarns(and Tall Tales)

The Shipyard IndentureJW Mullholland

The Shipyard IndentureJW Mullholland