1911 Started to acquire yards on the Clyde - the London and Glasgow Shipbuilding Co shipyard (including Robert Napier and Sons old yard, which had been vacated by William Beardmore and Co), together with the adjoining yard of Mackie and Thomson. These three Govan establishments were laid out as one large modern shipyard. The engineering works of the London and Glasgow Co. were greatly extended, and adapted for the construction of Diesel engines.

In 1946 the Harland & Wolff organisation was among the largest shipbuilding, marine and heavy engineering concerns in Scotland, employing a peak labour force of over 6000 workers at four major establishments in Glasgow, which were:

Finnieston Marine Engine Works, known locally as The Diesel Finnieston Marine Engine Works, known locally as The Diesel

Govan Shipbuilding Yard Govan Shipbuilding Yard

Govan Foundry, better known as The Glass House Govan Foundry, better known as The Glass House

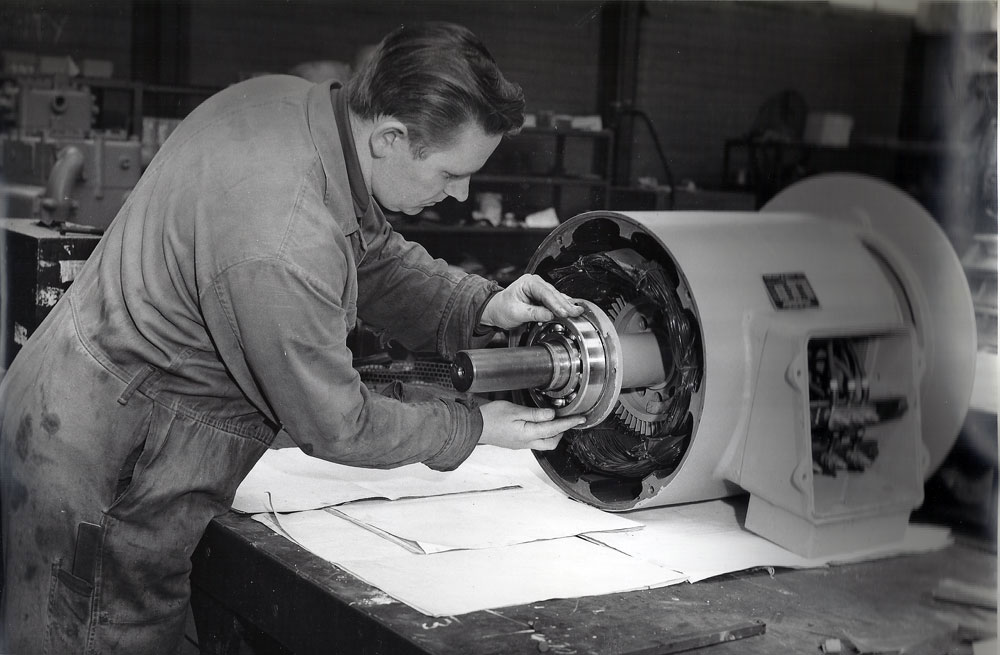

Scotstoun Gun Works which latterly built turbines for hydroelectric power stations. Scotstoun Gun Works which latterly built turbines for hydroelectric power stations.

Throughout the 1950s all the above works saw a regular intake of orders for the different products that each separate entity produced.

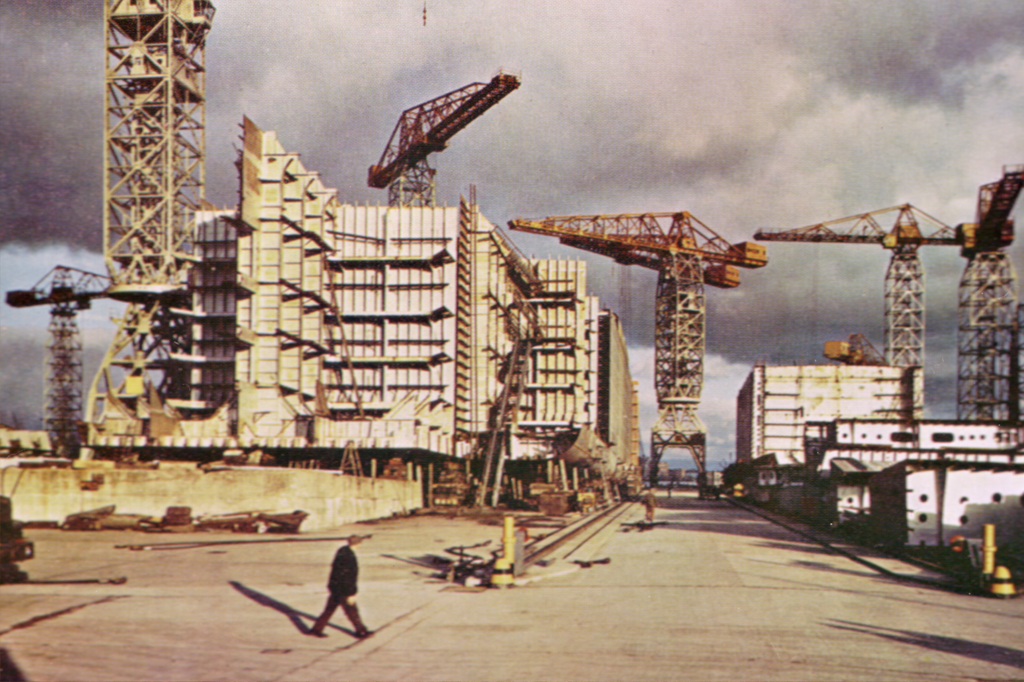

The Govan shipyard had the dubious distinction of being sited farthest away from the open sea than any other establishment on the River Clyde. Comprising six berths of varying lengths from 200-600ft in length, these were unique in that each slipway had its own mini dockgates which, when closed, allowed continuous working at the aft end of a ship under construction, irrespective of the state of the tide. Formerly the location of three small separate shipyards, these were procured by Harland & Wolff Ltd of Belfast in 1912, and were quickly consolidated to become their Govan yard. The location previously bore the names of Robert Napier and William Beardmore, respectively. The former was generally considered as the father of iron shipbuilding on the River Clyde, the latter regarded as one of the many successful archetypal Scottish industrial magnates of the nineteenth century.

The berths were served by a total of 16 fixed hammerhead cranes, some of which were 15 tons capacity. A plating shed with template loft above was located west of the berths. This building was separated from the main shipyard by Water Row, the very short road which lead from Govan Cross to the southern embarkation point for the Govan Ferry. This unique edifice, constructed of terracotta brickwork, bore an uncanny resemblance to the exterior facade of Ibrox Park football stadium, home of Glasgow Rangers FC. |

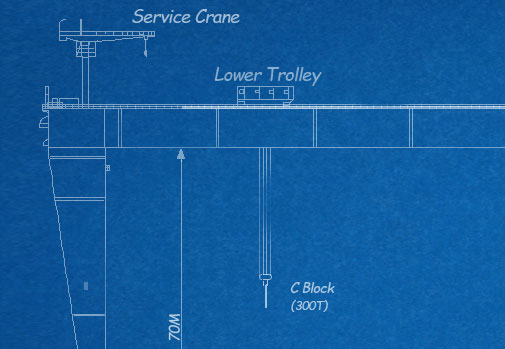

Within the confines of the main yard there existed a further plating shed, a covered prefabrication shop that was built in the early 1950s, miscellaneous outfit trades buildings, the drawing office, further adjacent workshops, and a fitting out basin served by 2 x 30 tons capacity, level luffing travelling cranes. It was a compact shipbuilding facility that regularly produced three to four cargo ships, or oil tankers each year from a total labour force of about 2,000 workers.

Post-war investment was minimal, and like virtually every other UK shipbuilding concern, was aimed specifically at replacing riveted methods of steelwork construction, with the technique of welding-hence the purchase of the new fabrication shed, some welding plant and very little other items of hardware.

Despite this niggardly application of funds to the improvement of facilities and working environment, the Govan shipyard had an excellent reputation for quality and delivery. Strikes occurring at the yard during the 1950s were symptomatic of the national malaise that then pervaded the industry. When settlement of such disputes was reached, the rapid return to work and the convivial atmosphere that mysteriously permeated the berths, sheds and outfit quays, contradicted the dank and gloomy aura that pervaded the buildings of the yard. The average age of the yard labour force always tended to be high as most men just could not afford to retire. Somehow this maturity resulted in a compliant acquiescence and tolerance of the spartan working conditions throughout the site. The summation of individual and collective craft skills were the hallmark of the shipyard, and this was manifestly endorsed in the fine range of ships built there since 1946.

Seldom if ever sharing the limelight with either its parent Belfast shipyard or the more famous publicity prone Clydeside shipbuilders, the Govan facility produced 54 ships totalling 504,481 g.r.t. from 1946 until 1962, including some 12 oil tankers for British Petroleum, 32% of this total was for export. Many of these vessels constructed were part of a series of two or more and all but one were motor ships engined by either Harland & Wolff Ltd in Glasgow or Belfast. The most handsome batch, indeed arguably among the finest looking cargo liners ever produced anywhere in the world, were the five 'B' class motor ships built for the British India Steam Navigation Co Ltd by the yard between 1959 and 1961 . With sloping sheer lines, raked superstructure, futuristic deck cranes, angled integral radar mast and funnel, these vessels had more in common with the profile of a yacht than that of a cargo liner. These ships had been designed by the renowned London firm of naval architects, Burness Corlett & Partners Ltd. The largest ship built at the yard was the British motor tanker Eskfield 18,851 g.r.t. launched on 21 May 1959. |

Maximum yearly production during this period was achieved at the yard in 1960, with the launching of two of these 'B' class cargo liners Barpeta 6736 g.r.t. and Bamora 6744 g.r.t., the ore carrier Daghestan 11,204 g.r.t., and the medium-sized oil tanker Norsk Drott 18,483 g.r.t., creating a total annual output of 43,167 g.r.t. A formidable statistic for a 'labour - intensive relic of shipbuilding obsolescence' that was still making regular profits for its Irish parent company even on its last contracts! 1961 saw the yearly total drop to three vessels including two handsome Bird class motor tankers for BP, and by 1962 the last orders were being processed through the yard. The launch of the Norwegian motor bulk carrier Belisland 10,862 g.r.t. (yard no. 1650G) on 26 September 1962, became the final such event at this traditional shipyard. By then the labour force had been whittled down to a few hundred men, only some of whom were retained on a 'care and maintenance' basis for a further 12 months, by which time the formal announcement of closure had been made by the Belfast parent company. Dismantling the berth craneage and some of the sheds commenced in 1964. The ship repair division of Alex Stephen & Sons Ltd acquired the fabrication shop. outfit basin and quayside cranes, where that company performed refit activities up until the mid 90's.

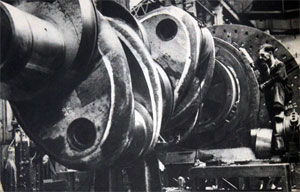

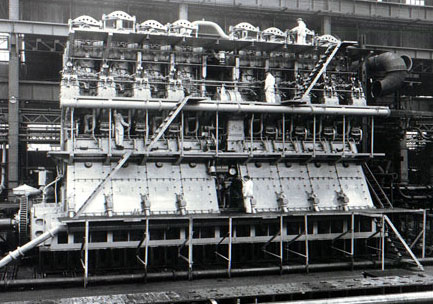

The Harland & Wolff engine works built large bore, slow and medium speed marine diesel engines, under licence to designs patented by the Danish company of Burmeister & Wain of Copenhagen. Employing well over 1000 workers throughout the 1950s, the labour force strove to meet the demand of the Group's Govan shipyard, and other UK shipbuilders. The workload profile was very similar to the shipyard on the other side of the river, working regular, incessant overtime when the order books were full. With routine annual intakes of apprentices up until 1960, the company, like most others, had a perceived stability about continuity of employment. Despite part of the customer base being outwith its parent group, 'the Diesel' was inextricably linked to the existence, output and longevity of the Govan shipyard. The attrition in numbers of workers employed at Finnieston was a subtle, if ostentatious, barometer to the future workload of the plant. 'The Diesel' didn't even build the engines for the last two vessels built at Harland & Wolff's Govan shipyard, these were built by the parent company in Belfast. It was therefore no surprise when closure of the engine works was announced in the early '60s. |

Some valuable items of specialised plant and machine tools, were transferred to the owning company in Belfast. Others were surreptitiously sold abroad to competitors or to local scrap dealers, and a highly skilled and motivated labour force was dispersed to man the 'sunrise' car plant at Linwood, or what other Clydeside industry that was then recruiting tradesmen. The site remained an empty shell for a number of years before being purchased and levelled on behalf of the Mirror group of newspapers, where it became the location for the printing and publishing of the 'Scottish Daily Record' and 'Sunday Mail'.

The 'Glass House' at Govan and 'Gun Works' at Scotstoun lingered on for a few more years as manufacturing facilities. The former, a foundry specialising in marine component manufacture' was razed to the ground in 1965' the latter continued to build equipment for hydroelectric power stations up until t967, when the site was acquired by British Leyland/Albion Motors Ltd. The large buildings remained under these owners and their successors, where vehicle components were still being manufactured in 1996. The west wall of the 'Gun Works' bore the name Harland & Wolff Limited in huge black letters well into the 1990s, and remained the only tangible reminder of a once famous company that was thought to be as permanent a fixture on Clydeside as was the rain on a Monday morning. |

The PartnersHarland, Wolff, Pirrie and Wilson

The PartnersHarland, Wolff, Pirrie and Wilson

The HatsChairmen, MD's, CEO's

The HatsChairmen, MD's, CEO's

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Frederick RebbeckChairman 1930-41 1944-62

Sir Charles PalmourChairman 1941-1944

Sir Charles PalmourChairman 1941-1944

John S BallieChairman 1962-1965

John S BallieChairman 1962-1965

Dr Dennis RebbeckChairman 1965-1966

Dr Dennis RebbeckChairman 1965-1966

Sir John MallabarChairman 1966-1970

Sir John MallabarChairman 1966-1970

Joe R EdwardsChairman 1970

Joe R EdwardsChairman 1970

Alan WattActing Chairman 1970-1971

Alan WattActing Chairman 1970-1971

Lord RochdaleChairman 1971- 1975

Lord RochdaleChairman 1971- 1975

Sir Brian MortonChairman 1975-1980

Sir Brian MortonChairman 1975-1980

Victor Alexander CookeChairman 1980-1981)

Victor Alexander CookeChairman 1980-1981)

Vivian WadsworthChairman 1981-1982

Vivian WadsworthChairman 1981-1982

Sir John ParkerChairman 1982-1992

Sir John ParkerChairman 1982-1992

Islandmen(and Women)

Islandmen(and Women)

Save our ShipyardSupport and solidarity

Save our ShipyardSupport and solidarity

The War MemorialsWe Will Remember Them

The War MemorialsWe Will Remember Them

The Bible Class

The Bible Class

Nicknames

Nicknames

The Yarns(and Tall Tales)

The Yarns(and Tall Tales)

The Shipyard IndentureJW Mullholland

The Shipyard IndentureJW Mullholland